About Cork

A renewable, environmentally friendly resource

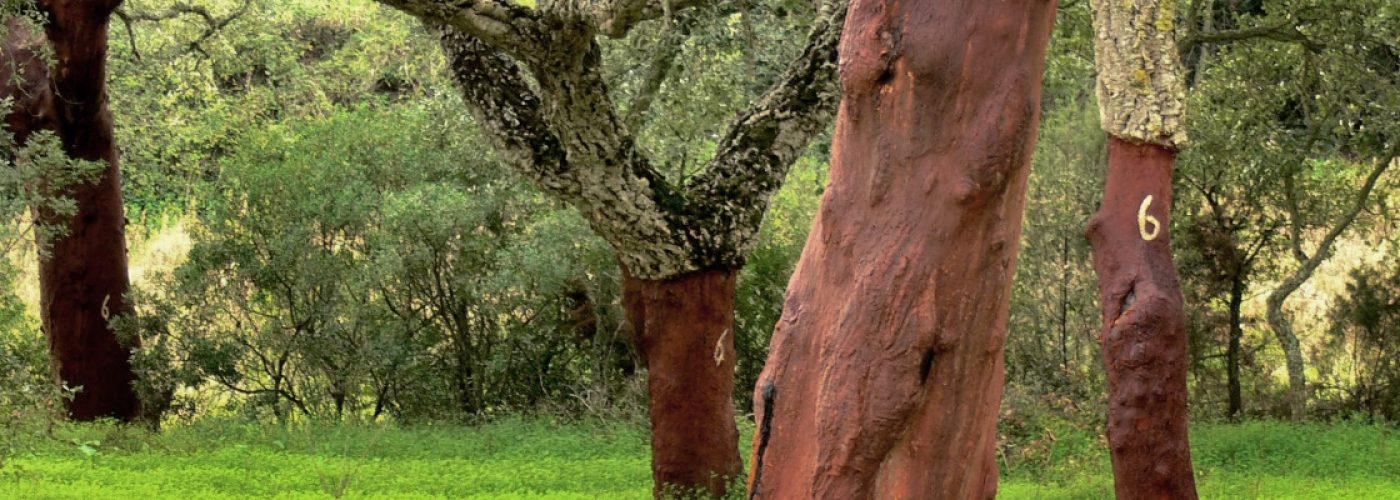

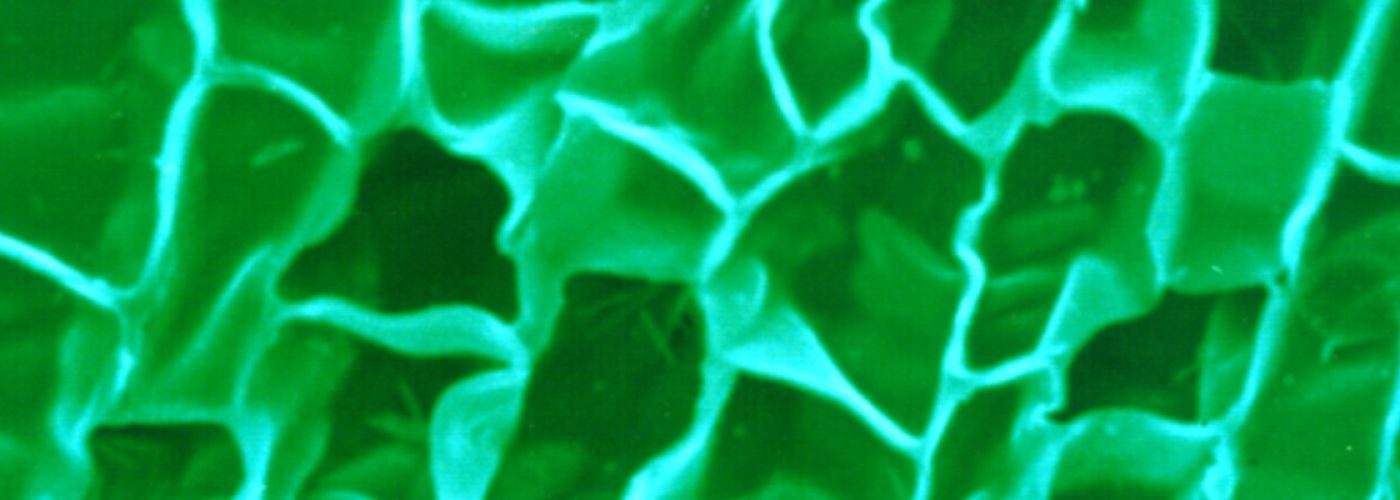

The cork oak tree, Quercus Suber L., which is mostly found in the Mediterranean region of the world, produces cork as its outer bark. The aggregation of cells that make up the bark is lined with alternating layers of cellulose and suberin and contains a gas that resembles air. The structure of cork has between 30 and 40 million cells per cubic centimeter.

About 2.5 million hectares are covered by cork oak woods, mostly in seven countries: Portugal, Algeria, Spain, Morocco, France, Italy, and Tunisia.

With a lifespan of over 300 years, this tree needs to be 25 years old before it can yield its first cork harvest. Every nine years, cork is sustainably removed from the trunk without causing any damage to the tree. A fresh coating of cork begins to form after harvest.

As environmental concerns grow, the cork oak is still the only tree whose bark can regrow after harvest without causing damage to the tree. It is a resource that is both environmentally beneficial and renewable. Additionally, a harvested cork tree fixes nearly five times as much carbon as an unharvested tree. The cork oak tree has a remarkable potential to retain carbon. Because of this remarkable quality, cork is a naturally sustainable product, and using it helps to protect a special ecosystem around the globe.

Characteristics

Cork, an amazing natural product.

The small cells that make up the characteristic honeycomb structure of the bark of the cork oak tree are entirely filled with air. The intrinsic properties of cork are derived from the structure and chemical composition of the extraordinarily strong and flexible membranes, which are also airtight and waterproof. Thirty to forty million cells per cubic centimeter make up the structure of cork.

Some of the most unique and useful characteristics of cork include:

Lightness: Gaseous matter makes up around 80% of the volume of cork, making it incredibly light and buoyant.

Resilience and Elasticity:

Because the cellular membranes are so pliable, the cork is both elastic and compressible. These and other attributes help to explain why cork has become so essential to the production of stoppers.

The gas inside the cells is compressed and significantly reduced in volume when the cork is put under a lot of pressure. The cork instantly returns to its initial volume after being removed from pressure.

Impermeability: Cork is impermeable to liquids and gasses due to the presence of suberin, a complex mixture of fatty acids and heavy organic alcohol. It may be regarded as one of the best seals available because it doesn’t decay.

Insulation: Of all natural materials, cork has one of the best thermal and acoustical insulating properties. This is because the gaseous components are enclosed in small, impermeable spaces that are separated from one another by a substance that can withstand moisture.

Fire retardant: Because cork doesn’t spread flames or emit harmful gases when it burns, it is a naturally occurring fire retardant.

Durability: Cork has a high coefficient of friction and is exceptionally resistant to wear. It is less susceptible to impact and friction than other hard surfaces because of its honeycomb structure.

Hypoallergenic: Since cork doesn’t collect dust, it doesn’t trigger allergies or endanger people with asthma.

Renewable, recyclable, and biodegradable: Cork is a naturally occurring raw material that is 100% renewable, recyclable, and biodegradable.

Cork oak forests

An example of sustainable development

Many animal and plant species, including some rare and endangered ones, find the ideal habitat in the cork oak woods, which are well-suited to the semi-arid regions of southern Europe and prevent desertification. To preserve biodiversity, prevent desertification, and advance social stability in the area, it is crucial to preserve cork oak forest regions and the cork’s economic viability. Approximately 100,000 people in southern Europe and northern Africa rely on cork oak woods both directly and indirectly, according to WWF.

With fresh plantations opening each year, cork production is guaranteed. It is illegal to cut down or remove trees without the strong intervention of the authorities. Portugal has been especially cautious with this resource, considering it generates almost half of the cork produced worldwide. The 13th century saw the introduction of the first Portuguese laws safeguarding cork oak trees.

Cork plays an important part in halting global warming. After being harvested, the tree’s cork bark regrows itself, and it is well known that a cork tree that has been harvested absorbs three to five times as much carbon. According to a recent study, cork forests in Portugal have the capacity to absorb 4.8 million tons of carbon annually, while cork forests in the Mediterranean region are thought to be able to absorb around 14 million tons.

The cork business is incredibly environmentally friendly. Not a single gram of cork is wasted; all of it is used. Cork by-products are employed in a variety of products (such as flooring, decorative items, and the automotive industry), and post-industrial and post-consumer recycling is a standard procedure. Energy can even be produced from cork dust.

Cork applications

A key material in many industries

Originally employed as fishing gear and wine stoppers centuries ago, cork has evolved into a vital component of numerous industries, including high-tech, sports, interior design, building, and even fashion and cosmetics.

The qualities of cork, whether it be natural, granulated, or agglomerated, are unique to no other single source, making it preferable to many synthetic alternatives and a necessary component for several applications.

Many of the applications for cork may be hidden from our view, and it can be tailored to different product standards and methods. For many different uses, including sealing, insulation, vibration control, weight reduction, sound dampening, gasketing, flotation, energy conservation, load bearing, polishing, pollution control, and many more, cork is truly an all-purpose problem solver.

Because cork is the greatest material for their particular and demanding uses, engineers, architects, builders, scientists, fashion designers, interior designers, and manufacturers of housewares, sporting goods, and leisure products choose it.